A switch panel could be considered a collection of light switches with a common faceplate. Switch panels give the appearance of being well organized while still maintaining the functionality of the various switches. Switch panels can run cables and cords through the bottom or rear panel holes. While the switches are located on the panel’s face, the cables, terminals, and other components are concealed inside the plastic, metal, or wooden casing. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of electric switches, membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

At ALMAX, we specialize in the design and manufacturing of electronic switches that merge precision engineering with customizable interface solutions. Our products are engineered to serve a wide range of industries, from medical device manufacturers to aerospace, industrial controls, and consumer electronics.

At CSI Keyboards, Inc., we have built our reputation around engineering electric switches that combine precision, reliability, and adaptability for a wide range of applications. Our switches are designed to meet the demands of industries where durability and accuracy are critical, from medical devices and industrial equipment to commercial electronics and beyond.

ABB is a manufacturer of low-voltage electrical switches. We offer relaying products, automation products—limit switches, rotary switches, toggle switches, disconnect switches, cam switches and safety switches for construction, process industries, industrial and OEM markets.

At Schneider Electric, we design and manufacture advanced electric switches that bring efficiency, reliability, and innovation to power control and automation systems worldwide. Our switches are engineered to meet the diverse needs of industrial, commercial, and residential environments, offering precise performance, safety, and durability.

At Powell® Electronics, we are dedicated to providing our customers with the best products and services possible. We understand that each customer has unique requirements, and we are committed to meeting those needs with high-quality products and exceptional customer service. Whether you need a standard electronic component or a custom-designed solution, we have the expertise and experience to...

Electric switches for industrial, residential and commercial uses are manufactured by Leviton Manufacturing Company. We offer switches with Amp ratings of 15, 20 and 30; they can include motor starter, lighted handle or pilot light, single-pole, double-pole, three-way and four-way.

More Switch Panel Manufacturers

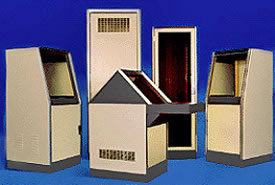

These panels often measure only a few inches in length and height, or they may be up to a foot or more in height and width. Switch panels in an airplane cockpit, for example, may take up many square feet.

Design of Switch Panels

Many manufacturers employ computer software to create specialized switch panels due to the huge demand, high necessity, and variety of uses for switch panels. Many materials, sizes, and shapes are available depending on the use. Cold-rolled sheet metal is used to make many industrial panels because it produces a thin, strong, lightweight, and long-lasting surface. The ideal material to use in difficult locations where the switch panel will be exposed to water and dust is stainless steel since it resists corrosion.

Other panels are created with material, color, and display in mind. Materials like acrylic, composite, and plastic components like ABS or PVC are used to make panels. Next, panels are colored through paint film or foil laminates. Finally, indicator lights or displays are added to switch panels.

Small carved holes or symbols, either in the switch actuator itself or on the panel, allow for electroluminescent, LED, or incandescent light illumination. The switches on the panel's surface are frequently rocker switches that, when swung in one direction so that one side is down and the other is elevated, click into place.

Toggle switches, which involve flipping an upright lever or handle into place, are a more conventional and industrial alternative. Push buttons can press small, shaped toggle buttons to activate switches. Most switches function similarly: a terminal is brought into contact with an electricity-conducting actuator, which closes the circuit and permits current to flow through the switch.

Types of Switch Panels

Slide Switches

A mechanical device called a slide switch is frequently used to regulate an electrical circuit. The switch is moved from an open position to a closed one or vice versa using a straightforward sliding motion. Slide switches are maintained-contact switches that stay in one condition until manually triggered into a different state.

Rotary Switches

Rotary switches link a working circuit inside a device to an electrical supply. They travel in a circle and have a few points where they can stop. In a single switch,rotary switches are utilized to regulate a variety of circuits.

The electrical charge enters the switch and is then sent to the circuit the switch is currently selecting. Rotary switches offer a reliable method in terms of mechanical control.

Pushbutton Switches:

A pushbutton switch is a mechanical device that uses manual pressure to activate an internal switching mechanism to regulate an electrical circuit. Depending on the needs of the design, they are available in some forms, sizes, and arrangements, including:

Dual Switches:

These switches have two specific buttons- one for ON and the other for OFF functions.

Momentary Switches:

Momentary switches feature a button that users must continuously push at regular intervals to keep the switch in the ON function.

Maintained/Latching Switches:

These switches feature one button. Users must press the button to turn the switch ON and, then, a second time to turn it back OFF.

Benefits of Switch Panels

Switch panels can handle complex electric controls. These panels can control the most complicated industrial setup if a professional team is engaged to develop them following the required specifications. Because switch panels are waterproof, one may install them indoors and outdoors since they won't rust or break down due to climatic changes. Location is critical where water can be present, such as bathroom sinks, kitchen sinks, etc. However, it must be properly fitted to ensure user safety and the panel's useful life.

Switch panels provide increased reliability through regular equipment monitoring and minute-by-minute data transmission to experts.

Hazard-proof switch panels eliminate the possibility of electrical shocks or fires (so it is safe to work in and around the panels).

Applications of Switch Panels

- Switch panels are frequently employed in industrial, commercial, and residential contexts. Switch panels are typically utilized as control panels for robotic assembly lines or industrial lines. Switch panels include electronic consoles and instrument panels found in vehicles and boats.

- Switch panel makers create a wide range of variants for use in leisure vehicles, marine applications, heavy equipment, emergency equipment, public transportation, and elsewhere.

Choosing the Proper Switch Panel Supplier

To ensure you have the most positive outcome when purchasing switch panels from a switch panel supplier, it is important to compare several companies using our directory of switch panel suppliers. Each switch panel supplier has a business profile page illustrating their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or request a quote. Review each switch panel business website using our proprietary website previewer for a better idea of what each company specializes in. Then, use our simple RFQ form to contact multiple switch panel businesses with the same form.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

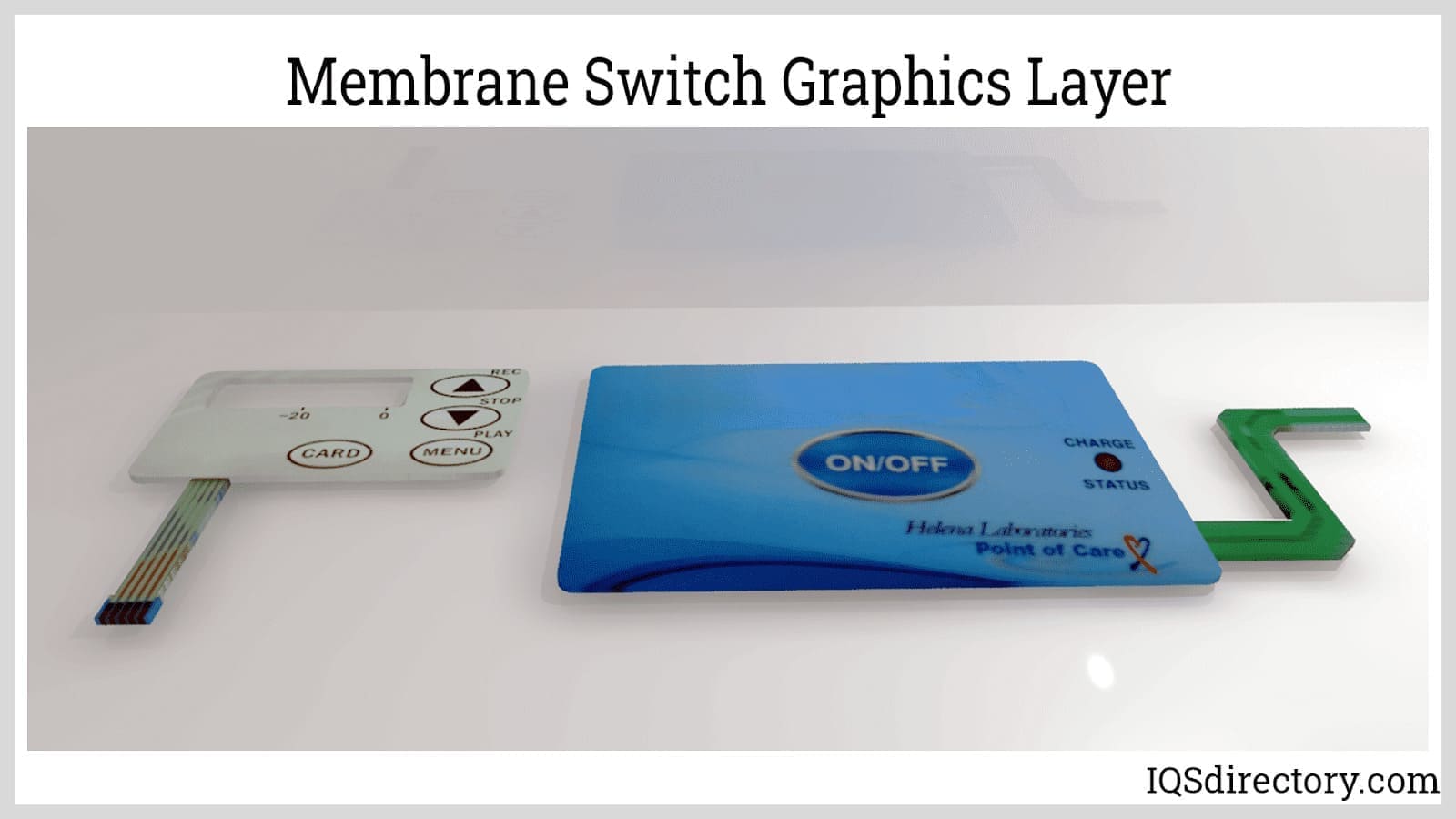

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services