Rotary switches allow multiple circuits to be controlled by a single switch. Rotary switches rotate in a circle and have multiple stopping points. Rotary switches have many advantages over ordinary switches. This type of actuator can turn circuits ON or OFF depending on the position, and there are numerous possible actuation positions. Rotary switches can allow multiple contacts to occur simultaneously on a single switch position. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of electric switches, membrane switches, graphic overlays, and custom labels. We nimbly handle projects big and small and have the uncommon ability to translate what our customers need into high-quality, high-precision outcomes.

At ALMAX, we specialize in the design and manufacturing of electronic switches that merge precision engineering with customizable interface solutions. Our products are engineered to serve a wide range of industries, from medical device manufacturers to aerospace, industrial controls, and consumer electronics.

At CSI Keyboards, Inc., we have built our reputation around engineering electric switches that combine precision, reliability, and adaptability for a wide range of applications. Our switches are designed to meet the demands of industries where durability and accuracy are critical, from medical devices and industrial equipment to commercial electronics and beyond.

ABB is a manufacturer of low-voltage electrical switches. We offer relaying products, automation products—limit switches, rotary switches, toggle switches, disconnect switches, cam switches and safety switches for construction, process industries, industrial and OEM markets.

At Schneider Electric, we design and manufacture advanced electric switches that bring efficiency, reliability, and innovation to power control and automation systems worldwide. Our switches are engineered to meet the diverse needs of industrial, commercial, and residential environments, offering precise performance, safety, and durability.

At Powell® Electronics, we are dedicated to providing our customers with the best products and services possible. We understand that each customer has unique requirements, and we are committed to meeting those needs with high-quality products and exceptional customer service. Whether you need a standard electronic component or a custom-designed solution, we have the expertise and experience to...

Electric switches for industrial, residential and commercial uses are manufactured by Leviton Manufacturing Company. We offer switches with Amp ratings of 15, 20 and 30; they can include motor starter, lighted handle or pilot light, single-pole, double-pole, three-way and four-way.

More Rotary Switch Manufacturers

Rotary switches are a vital component in a wide variety of electrical and electronic equipment, offering users reliable and precise control over circuit connections. Although rotary switches are common in industrial equipment—such as automation panels, test instruments, and heavy machinery—they are also present in consumer products, including the fan speed controls in vehicles, home appliances, and audio-visual devices. While today’s sophisticated switching operations are often managed by digital devices like touchscreens, mechanical rotary switches remain indispensable in applications where reliability, safety, and tactile feedback are key priorities. This is especially true in environments where a computer malfunction could pose a critical safety risk, making the robust, fail-safe characteristics of rotary switches highly valuable.

What Is a Rotary Switch and How Does It Work?

A rotary switch is an electromechanical device designed to connect one input to one of several outputs by rotating a knob or spindle. These switches offer multiple positions, each corresponding to a different circuit path. Their design enables efficient management of complex switching tasks, such as selecting operating modes, channel switching, or setting variable parameters in electrical circuits.

Components of a Rotary Switch

Understanding the anatomy of a rotary switch can help users and engineers make informed purchasing decisions. Rotary switches typically contain the following key components:

- Spindle (or Shaft): The central axis around which the switch rotates, often featuring a knob or actuator for manual operation.

- Rotors: Mounted on the spindle, rotors are discs or arms that carry electrical contacts. Each rotor’s arm can make contact with terminals at various switch positions, allowing different circuits to be engaged.

- Terminals: Electrical connection points for the switch’s input and output paths, usually arranged in a circular pattern.

- Detent Mechanism: This system ensures the switch “clicks” firmly into set positions, preventing accidental changes and providing tactile feedback. A wheel with notches or grooves, combined with a spring-loaded ball bearing or piece of spring steel, secures the position when the switch is rotated.

- Decks (or Wafers): Rotary switches can have multiple decks, each enabling control over additional circuits. Decks are stacked along the spindle, with each adding a layer of switching capability.

The spindle allows the rotors to rotate among various positions, offering a wide range of switching options. Depending on the number of rotors and decks, a rotary switch can possess dozens of unique positions, each connecting to a distinct circuit—making them ideal for complex selection tasks.

What Are the Main Types of Rotary Switches?

There are several types of rotary switches, designed to accommodate different application requirements:

- Single-Pole Rotary Switches: Control a single circuit, commonly used in basic on/off or multi-way selection applications.

- Multi-Pole Rotary Switches: Control multiple independent circuits simultaneously for advanced switching operations.

- Single-Deck vs. Multi-Deck Rotary Switches: Single-deck switches manage one circuit layer, while multi-deck variants allow for more complex, multi-layered control.

- Enclosed vs. Open Frame: Enclosed rotary switches provide protection against dust and debris, while open-frame designs offer easier access and customization.

Selection Criteria of a Rotary Switch

Choosing the appropriate rotary switch is essential for ensuring performance, durability, and safety in your application. Whether you are designing new equipment or upgrading existing machinery, consider the following key specifications and decision factors:

1. Physical Specifications

Number of Poles

The number of independent circuits that can be controlled simultaneously is determined by the number of poles. The “pole” refers to the input or common terminal, representing how many separate circuits a switch can regulate. For instance, a single pole (SP) rotary switch controls one circuit, while double pole (DP) and triple pole (3P) switches can manage two and three circuits, respectively. Large industrial rotary switches may offer even more poles for complex multi-circuit applications.

Mechanical Life and Electrical Life

Mechanical life refers to the number of operational cycles a rotary switch can endure before mechanical wear affects performance. Electrical life, by contrast, denotes the number of cycles during which the switch can reliably open and close circuits under load. It is common for mechanical life to outlast electrical life, especially in high-power or high-frequency switching environments. When selecting rotary switches for demanding industrial settings, always consult manufacturer data on both mechanical and electrical life expectancies.

Angle Between Positions

Switch position spacing is defined by the angular separation, expressed in degrees. For example, a 4-position rotary switch typically features a 90° angle between each position, while a switch with 100 positions would have a 3.6° angle (based on 360° in a full circle). Selecting the right angle ensures precise user control and compatibility with panel layouts or user interface requirements.

Number of Decks

The number of decks (also known as modules, wafers, or sections) refers to how many independent switching layers are stacked on a single shaft. Single-deck rotary switches control one circuit path, while multi-deck options can manage multiple circuits at once, making them ideal for complex control panels, audio mixing equipment, and multi-channel selection systems.

Number of Poles Per Deck

This specification indicates how many independent circuits each deck can control. In rotary switch terminology, “ways” are often used instead of “throws” to describe output connections. For example, a single pole may control anywhere from one to twelve “ways” (or more), depending on the design. The number of terminals required will determine the number of switch positions available.

Switch Frame

There are two primary frame types for rotary switches:

- Open Frame: Features visible moving elements, facilitating self-cleaning contacts and flexible, custom configurations. Open-frame rotary switches are preferred where easy maintenance and inspection are needed.

- Enclosed Frame: Encases internal components to protect against dust, debris, and contamination. These switches are typically more compact and cost-effective, making them suitable for consumer electronics, automotive dashboards, and sealed environments.

2. Electrical Specifications and Material Considerations

Current and Voltage Ratings

When selecting a rotary switch, it is crucial to check the maximum current and voltage ratings for both AC (alternating current) and DC (direct current) loads. The maximum current rating (in amps) defines the highest continuous current the switch can handle with contacts closed, while voltage ratings specify the maximum safe voltage the device can withstand. Exceeding these ratings may lead to overheating, contact degradation, or unsafe operation.

Contact Material

Electrical contacts in rotary switches are typically constructed from metals with excellent conductivity and resistance to oxidation. Common materials include silver, gold, and other precious or noble metals. High-quality contact materials ensure low contact resistance, reduced wear, and long-term reliability—especially in demanding industrial and high-frequency switching applications.

Switching Under Load and Arc Suppression

Switching positions while under electrical load can generate arcs—brief electrical discharges that can erode contact surfaces over time. For applications with frequent or high-power switching, choose rotary switches designed with arc-resistant contact materials or built-in arc suppression features. This will extend the life of the switch and reduce maintenance costs.

Applications and Use Cases for Rotary Switches

Rotary switches are used across a wide range of industries and applications. Their unique characteristics make them the preferred choice for:

- Industrial Control Panels: Multi-position rotary switches are essential for selecting operating modes, adjusting parameters, or switching between machine functions in manufacturing and process control equipment.

- Test and Measurement Instruments: Used in multimeters, oscilloscopes, and other lab equipment to select measurement ranges, channels, or modes.

- Audio and Broadcast Equipment: Channel selectors, audio input selectors, and mixing consoles frequently employ rotary switches for smooth, reliable selection.

- Automotive and Transportation: Fan speed controls, lighting selectors, and dashboard controls commonly use rotary switches for tactile, intuitive user interfaces.

- Consumer Appliances: Rotary switches are found in kitchen appliances (blenders, ovens, washing machines), HVAC systems, and lighting dimmers, providing user-friendly multi-setting control.

- Medical Devices: In critical medical equipment, rotary switches offer fail-safe operation where digital controls may not be suitable due to reliability or safety requirements.

When Should You Choose a Rotary Switch Over Other Types?

Rotary switches are ideal when your application requires:

- Multiple discrete positions for selecting between several circuits or functions

- Intuitive, tactile feedback for operators

- High reliability in harsh environments or mission-critical systems

- Simple, robust mechanical construction with minimal risk of digital or software failure

Not sure which switch type is right for your project? Compare rotary switches to other industrial switch types to make an informed decision.

Benefits of Using Rotary Switches

Rotary switches offer several significant advantages over other switching devices, making them a popular choice among engineers and equipment designers:

- Versatility: With single or multiple poles and decks, rotary switches can be tailored to simple or complex control requirements.

- Durability and Reliability: Mechanical construction and quality materials ensure dependable long-term operation, even in challenging environments.

- Tactile Feedback: The detent mechanism provides a reassuring “click” at each position, reducing user error and preventing accidental changes.

- Space Efficiency: Multi-deck rotary switches allow for dense, multi-circuit control from a single panel cutout, saving valuable space in control enclosures.

- Customizability: Many manufacturers offer custom configurations, including special contact arrangements, labeling, and mounting options to suit specific application needs.

Rotary Switches vs. Digital Switching—Which Is Better?

While digital switches and touch interfaces offer advanced programmability and sleek aesthetics, rotary switches deliver unmatched reliability, especially in safety-critical or harsh industrial environments. Consider your application’s requirements for reliability, user experience, and failure tolerance when choosing between mechanical and electronic switching solutions.

How to Select the Best Rotary Switch for Your Application

With a wide array of rotary switch designs, features, and manufacturers available, it’s important to evaluate your application’s needs thoroughly. Follow these steps for a successful selection:

- Define Your Requirements: Determine the number of circuits, positions, and switching functions needed. Consider electrical ratings, durability, and environmental conditions.

- Compare Physical and Electrical Specifications: Assess poles, decks, current/voltage ratings, contact materials, and the type of detent mechanism.

- Review Application-Specific Needs: Factor in the required mounting method, actuation style (knob, lever, shaft), and any special labeling or customization.

- Evaluate Manufacturer Capabilities: Research suppliers for quality certifications, custom engineering support, and delivery timelines.

- Request Samples and Test: Before committing to a large purchase, request product samples for prototyping and field testing.

Additional Rotary Switch Details for Consideration

Beyond basic specifications, consider the following advanced factors for optimal performance and longevity:

- Ingress Protection (IP) Ratings: For outdoor or harsh environments, choose rotary switches with appropriate IP ratings to prevent moisture and dust ingress.

- Mounting Style: Panel mount, PCB mount, or surface mount options affect installation methods and compatibility with existing systems.

- Actuator Design: Knobs, levers, and shafts can be selected for ergonomic operation and user preference.

- Labeling and Marking: Clear, durable position indicators enhance usability and reduce operator error.

- Compliance and Certifications: Ensure switches meet relevant industry standards (UL, CE, RoHS, etc.) for safety and environmental compliance.

When switching contact positions under load—where low-level power is being transferred—an electrical arc may occur. This arc can cause contact wear over time. To minimize issues, choose switches with robust contact materials and consider arc suppression features for high-frequency or high-power applications.

Choosing the Right Rotary Switch Manufacturer

To ensure the best outcome when purchasing rotary switches, it’s essential to evaluate several manufacturers and suppliers. Use our comprehensive rotary switch manufacturers directory to compare company profiles, areas of expertise, and product capabilities.

Each manufacturer’s profile page highlights their unique capabilities, certifications, lead times, and customization options. Use the integrated contact form to request detailed information, custom quotes, or technical support directly from the supplier. Our patented website previewer allows you to explore each business’s website, product lines, and support resources before making your decision. When ready, leverage our easy RFQ (Request for Quote) form to reach out to multiple rotary switch companies with a single inquiry—saving time and ensuring you get the best value.

Frequently Asked Questions About Rotary Switches

- What are the main advantages of rotary switches over toggle switches? Rotary switches offer multi-position control, greater circuit complexity, and tactile feedback, making them ideal for applications requiring more than simple on/off switching.

- Can I customize rotary switches for my equipment? Many manufacturers offer custom rotary switch solutions, including special contact arrangements, labeling, and mounting options. Contact suppliers early to discuss your requirements.

- What maintenance is required for rotary switches? Periodic inspection for contact wear and cleaning may be necessary, especially in open-frame models. Enclosed switches require less maintenance due to their sealed design.

- Are rotary switches suitable for high-voltage or high-current applications? Yes, but always verify the switch’s voltage and current ratings to ensure compatibility with your system. For demanding environments, select switches with robust contact materials and arc suppression features.

Conclusion: Why Rotary Switches Remain Essential in Modern Design

Despite advances in digital controls and touchscreen interfaces, rotary switches remain a cornerstone in electrical and electronic system design. Their unique combination of versatility, reliability, tactile feedback, and customizability ensures they are the go-to solution for industrial automation, test equipment, consumer products, and more. By understanding the key specifications, use cases, and decision factors, you can select the perfect rotary switch for your project—delivering safety, longevity, and user-friendly control for years to come.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

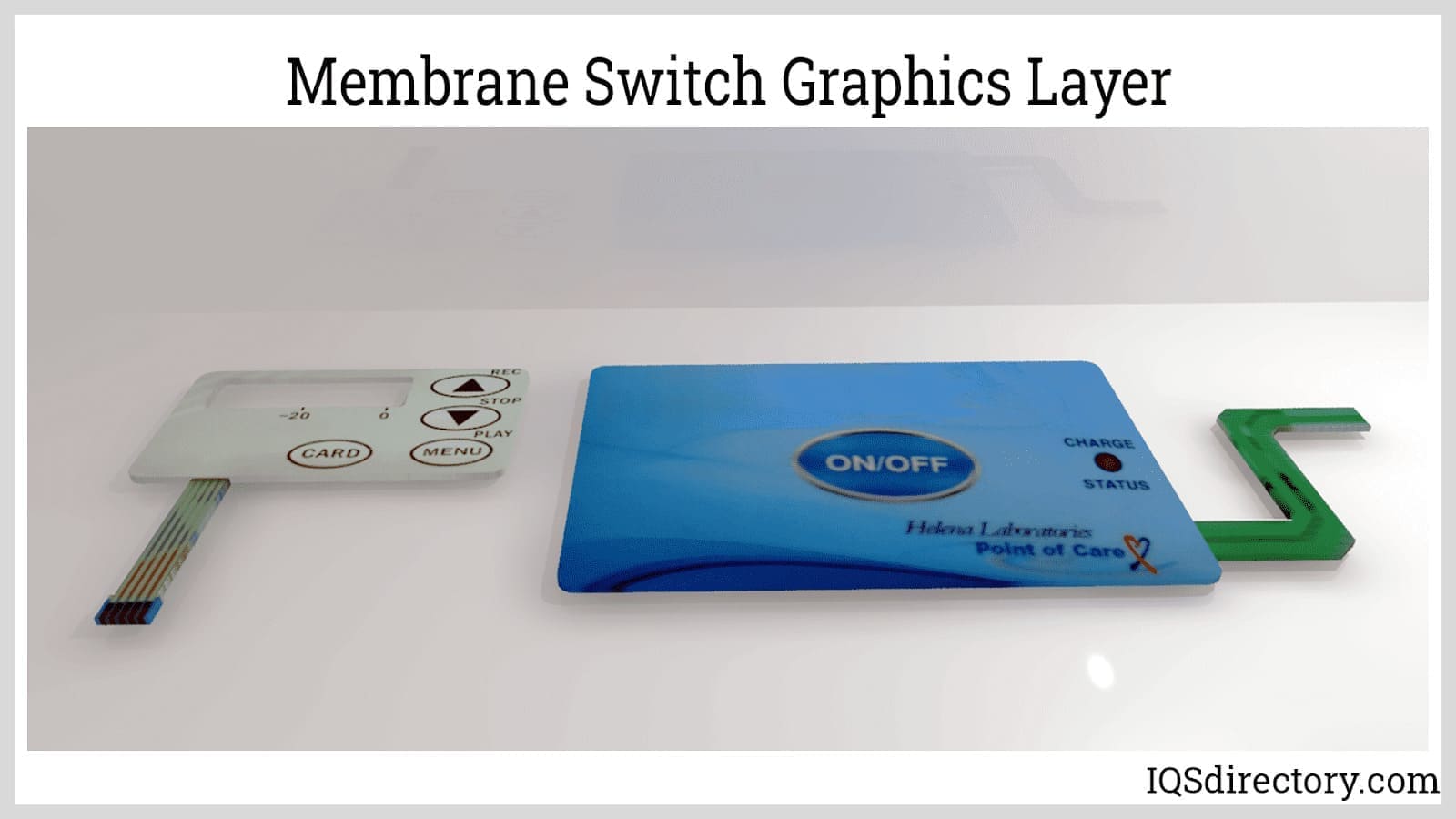

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services