More Electric Switch Manufacturers

Note: Some people refer to electric switches as “circuit breakers.” This comparison stems from the fact that, like a circuit breaker, a switch disrupts and alters, or “breaks,” a circuit when it changes from open to closed. However, electric switches and circuit breakers are not identical. Circuit breakers are specialized devices designed to safely manage electric currents and protect circuits from overload or electrical faults, whereas electric switches primarily provide manual or automatic control over the flow of electricity. Understanding the differences between these two essential components can help you make informed decisions when selecting electrical protection and control devices for your application.

History of Electric Switches

Electric switches have a long and innovative history, born out of the need to safely and reliably control the flow of electricity. The earliest electric switches were simple light switches, invented by Thomas Edison, one of the premier inventors of the light bulb and pioneers of electrical engineering. In preparation for the 1880 New Year’s celebration, Edison created a number of electrical components for a light display. Among these components were switches specifically designed to make lighting control more practical and user-friendly.

Soon after Edison developed his switches, John Henry Holmes, a British engineer, invented the quick break switch. This innovation prevented residue buildup from electrical arcing, significantly enhancing the durability and lifespan of switches and improving electrical safety. The quick break mechanism also sped up the process by reducing the time needed for two electric contacts to meet within a circuit. By the late 19th century, push button switches had become quite popular, helping to popularize electrically powered lighting in homes and businesses.

In 1917, New York-based inventors Morris Goldberg and William J. Newton created the toggle switch, inspired by the quick break switch. Even today, the toggle switch remains a common feature in North American homes, serving as the everyday light switch and a staple of residential and commercial wiring systems.

Since the early 20th century, the fundamental concept of electronic switches has remained largely unchanged, but the methods we use to control them have evolved dramatically. Today, with the advancements in computer technology, smart home automation, and modern electronics, we can activate switches remotely via Wi-Fi or Bluetooth, utilize sensors to respond to environmental changes, send digital signals, and much more. The integration of Internet of Things (IoT) technology is further expanding the capabilities of electrical switches, enabling centralized control, energy management, and data monitoring. Looking ahead, innovations in materials science, miniaturization, and connectivity are set to redefine electric switch technology even further, enabling safer, more efficient, and highly customizable solutions for both industrial and consumer applications.

Electric Switch Design

Manufacturers design and produce electronic switches tailored to an extensive range of specifications, including available space, operating environment, accessibility requirements, voltage and current ratings, and the number of electronic circuits to control. The design process is crucial for ensuring the switch’s performance, reliability, and safety within its intended application.

To design the ideal electric switch for your needs, manufacturers offer a variety of customization options. These include:

- Internal Configuration: The arrangement of contacts and terminals inside the switch, impacting how the switch connects or disconnects circuits.

- Control Mechanisms: Mechanical, electronic, or sensory actuators that determine how the switch is operated (such as toggles, push-buttons, rockers, rotary knobs, or touchscreens).

- Housings: The protective enclosure for the switch, which can be made from materials like plastic, metal, or wood to ensure durability, electrical insulation, and aesthetic appeal.

- Size and Form Factor: Compact micro-switches for PCB mounting, industrial-scale switches for heavy machinery, or ergonomically designed switches for frequent human interaction.

- Environmental Protection: IP-rated enclosures for water, dust, and chemical resistance, as well as features for shock and vibration tolerance.

- User Accessibility: Large actuators for ease of use, tactile feedback, backlighting, or braille labeling for enhanced accessibility.

- Connectivity: Integration with smart control systems, wireless protocols, or modular switch panels for centralized management.

For instance, while many switches function independently, manufacturers can also design them to be interconnected in complex control panels, enhancing circuit flexibility and system scalability. Additionally, switches can vary greatly in complexity—from the simplest types, which require direct physical contact, to advanced proximity switches or photoelectric switches that operate without touch, relying on magnetic, optical, or capacitive sensing technologies.

Manufacturers can create switches with components hidden in housings made from wood, plastic, or metal for safety, environmental protection, or aesthetic purposes, all while keeping the switch accessible for users or service personnel. They can create switches so small they require a miniature tool—like an inkless pen—to be accessed and operated, or design robust, heavy-duty switches that can be operated with gloves or require special force for industrial safety. To explore the various electric switch design options, consult with potential suppliers and request custom quotes or design consultations based on your project’s unique requirements.

Key Features of Electric Switches

Electric switches come in various types, but most share several essential components that determine their function and performance:

- Conducting Materials: The materials used for the switch contacts must be highly conductive and corrosion resistant, such as copper, silver, or gold-plated alloys. Metal corrosion can lead to insulating oxide buildup, inhibiting proper switch function. Conducting materials are also selected for abrasion resistance, mechanical strength, low toxicity, and, ideally, cost-effectiveness.

- Actuators: These are the moving components that allow users or automated systems to operate the switch. Actuators come in a variety of forms, including toggles, dollies, rockers, push-buttons, rotary knobs, sliders, and touch-sensitive panels. The actuator’s design is critical for providing tactile feedback, ergonomic operation, and long-term durability.

- Terminals: The points where electric conductors connect to the switch and external circuits. Terminals may be simple wire ends, screw terminals, or equipped with fasteners and connectors for secure attachment and ease of installation.

- Housing or Enclosure: Designed for user safety and environmental protection, enclosures may be made from insulating plastics, metals, or composite materials and can include gaskets or seals for water, dust, and chemical resistance (e.g., IP65, IP67 ratings).

- Contact Mechanisms: The internal arrangement of switch contacts determines whether a switch is single-pole, double-pole, single-throw, double-throw, etc. This configuration impacts the switch’s ability to route or manage multiple circuits.

Additional features may include built-in indicator lights, backlighting for nighttime visibility, locking mechanisms for security, and modular construction for easy replacement or expansion. For applications requiring the highest reliability, such as medical devices or aerospace systems, manufacturers may provide switches with redundant contacts, gold-plated terminals, or hermetically sealed enclosures.

How Electric Switches Work

At their core, electric switches operate by either permitting or halting the flow of electric current within a circuit, following the principle of open or closed circuits. When a switch is in the “closed” position, it completes the circuit, creating a continuous pathway for electricity to travel. This connection of the switch’s terminals allows the current to flow freely, ensuring the load connected to the circuit receives power. In this state, the switch is actively conducting electricity and the device or system—such as a light, motor, or control relay—is powered on.

Conversely, when switches are in the “open” position, they break the circuits, disconnecting the terminals from each other. As a result, the flow of electric current is interrupted, and the loads are deprived of power. In this state, the switches act as insulators, preventing electricity from passing through and ensuring the device remains off or inactive. This function is fundamental for both safety and energy management.

The actuators of the switch—such as toggles, buttons, or levers—are used to change the switch’s state. When users or automated processes move the actuator to the “on” position, the switch closes, completing the circuit and allowing current to flow. Conversely, moving the actuator to the “off” position opens the switch, interrupting the circuit and stopping the current flow. Some advanced switches, like momentary or latching types, temporarily change state based on user input or control logic.

Our ability to open and close circuits is essential for controlling electrical devices and systems. Electric switches are used extensively in countless applications, from simple household lighting switches to complex industrial control systems. They offer a convenient and safe way to regulate the flow of electricity and power various electrical devices.

Types of Electric Switches

A major variable in all electrical switches is the type of actuator, or how they are controlled. Based on this, switches can be grouped into physically controlled, mechanically controlled, and electronically controlled categories. Understanding the different types of switches and their operating mechanisms is crucial when selecting the right component for your specific application or when researching the best electric switch solutions for your project.

Mechanically Controlled Switch Types

- Toggle Switches: Control the flow of electrical power by shifting between two or more positions. The simplest toggle switches alternate between off and on, while more complex versions offer multiple positions for multi-way switching. Toggle switches are versatile and suitable for controlling household lights, managing industrial machinery, making quick connections and disconnections, and fast switching. They’re particularly useful when control devices are mounted in proximity. Many toggle switches can handle switching 250 VAC at currents around 1 amp, but industrial-grade toggle switches are available for higher loads and specialized applications.

- Push Button Switches: Feature actuators in the form of flush, recessed, or raised buttons. These switches provide two-position control, activated by pressing the button. When pressed, the button completes a connection in the internal circuit, turning on the connected device. A spring inside the switch pushes the button back to its “out” or off position, breaking the circuit and turning off the device. Push button switches are ideal for momentary connections, as in doorbells, calculators, or control panels.

- Slide Switches: Interrupt the flow of current by moving from position to position in a straight line, offering at least two positions: “on” and “off.” Slide switches are common in consumer electronics, audio equipment, and small appliances.

- Waterproof Switches: Crafted to withstand water, shock, salt, corrosion, and vibrations, these switches are securely encased in watertight housing and are used in outdoor, marine, or industrial environments where exposure to moisture or harsh elements is a concern.

- Rotary Switches: Operated with a rotating control knob, these switches are ideal for applications needing more options than just on and off, as they can be turned to multiple positions. Rotary switches are used in audio equipment, instrumentation, and multi-speed fan controls, offering flexible circuit selection.

- Rocker Switches: Switches that lift at one end when the other is pressed down. Rocker switches are commonly found in power strips, appliances, and automotive dashboards, offering easy operation and clear visual feedback.

- DIP (Dual In-Line Package) Switches: Manually operated switches that function as rocker, slide, or rotary switches, commonly found in devices like remote controls, garage door openers, and programmable logic controllers. “DIP switches” often refer to single switches or arrays mounted on circuit boards, and the device housing these switches is known as a switch panel.

- Speed Switches: Monitor the rotational motion and speed of shafts or other rotating components. Once a component reaches a predetermined speed, the control circuit is activated. These switches are vital for industrial automation, conveyor systems, and motor protection.

- Keylock Switches: A subtype of rotary switches, commonly used in security applications. Operation requires a key, and the switch may provide multiple functions accessible at different positions. Keylock switches are used in elevators, machinery lockouts, and secure control panels.

- Limit Switches: Devices that prevent objects from moving beyond a predetermined point. They are widely used in industrial automation, robotics, and safety interlocks.

Electronically Controlled Switch Types

- Switch Relays: Electromechanical or solid-state switches that are controlled electronically, allowing circuits to be switched remotely or automatically as part of larger control systems.

- Signal Switches: Absorb information from the environment (such as temperature, motion, or light) to determine how to adjust their circuits. Used in thermostats, security lights, medical devices, and automation systems.

- Semiconductor Transistors: The most prevalent type of electronic switches, found in computing components, processors, and digital circuits. Transistors act as electronic switches for high-speed signal processing and logic operations.

- Remote Electrical Switches: Enable control of circuits from a distance, commonly via wireless remotes, smartphone apps, or smart home hubs. Used in home automation, building management, and security systems.

- Proximity Switches: Activate when they detect an object approaching, using magnetic, capacitive, or optical sensors. Essential for automation, robotics, and safety interlocks in manufacturing and process control.

- Temperature Switches: Utilize bimetallic strips or semiconductors to switch circuits based on temperature thresholds, offering automatic thermal protection for motors, HVAC systems, and industrial equipment.

Other Electric Switch Types

- Single-Pole Switches: Designed for general use, featuring two actuator positions: “on” and “off.” Configurations include single throw (SPST) or double throw (SPDT), indicating the number of terminals that complete the circuit. Single-pole switches are common in residential and commercial lighting and power distribution.

- Double Pole Switches: Function with two actuators that can connect or disconnect two circuits simultaneously. Used for appliances with multiple mechanical components or for switching 240-volt circuits. Configurations include single-throw (DPST) or double-throw (DPDT).

- Joystick Switches: Feature a lever that can move across multiple axes, providing a greater range of control options. Used in motion control devices, such as industrial cranes, video game controllers, and robotics.

- Switch Panels: Designed to manage multiple electronic circuits and can include various types of switches, all housed within a single enclosure for centralized control.

- Air Switches: Use air as insulation between open contacts to interrupt the circuit, offering enhanced safety in wet or hazardous locations.

- Modular Switches: Feature multiple ports with various connectivity options, available in a range of shapes, sizes, and colors for residential, commercial, and industrial applications.

- Load Break Switches: Designed to disconnect circuits at preset currents, often with or without fuses, providing safe isolation for high-power electrical distribution systems.

- Transfer Switches: Built to alternate loads between two power sources—such as utility power and generator backup—either manually or automatically. Automatic transfer switches (ATS) are integral to uninterrupted power supply systems in hospitals, data centers, and critical infrastructure.

Applications of Electric Switches

Electric switches are indispensable across a vast spectrum of applications, from everyday household use to cutting-edge industrial and commercial systems. Here’s an in-depth look at how electric switches are used in different sectors:

- Residential: Managing lighting (wall switches, dimmers), controlling household appliances (fans, kitchen gadgets, smart home hubs), and providing safety shutoffs for electrical circuits. Modern homes leverage smart switches for remote control, scheduling, and energy monitoring.

- Consumer Electronics: Powering devices such as computers, laptops (power and reset buttons), televisions, gaming consoles, and portable electronics. Touch-sensitive and capacitive switches are increasingly common in smartphones, tablets, and wearables.

- Industrial Automation: Managing heavy machinery and process equipment, ensuring safe and efficient operation in manufacturing, assembly lines, and robotics. Industrial switches must withstand harsh conditions, frequent use, and high currents.

- Automotive: Operating functions such as headlights, turn signals, windows, power seats, mirrors, infotainment controls, and dashboard interfaces. Automotive-grade switches are designed for durability, vibration resistance, and ergonomic operation.

- Data and Telecommunications: Electric switches are vital in switching and routing equipment, telephone exchanges, and data centers, enabling rapid connection and disconnection of circuits and network paths.

- Medical Equipment: Providing reliable control in critical devices such as ventilators, diagnostic machines, infusion pumps, and patient monitoring systems, where safety and reliability are paramount.

- Security and Safety Systems: Used in alarm systems, emergency shutoffs, fire control systems, and access control panels. Tamper-proof and keylock switches help prevent unauthorized access or operation.

- Power Distribution and Transmission: High-capacity load break switches and transfer switches are crucial for managing power grids, substations, and backup power systems in commercial, industrial, and utility environments.

- Aerospace and Defense: Electric switches are designed for extreme reliability, vibration resistance, and miniaturization, controlling avionics systems, navigation, and communication equipment.

- Renewable Energy: In solar, wind, and battery storage systems, switches manage power flow, isolate circuits for maintenance, and integrate with smart grid infrastructure.

Benefits of Electric Switches

Choosing the right electric switch can provide a range of benefits for your project or system:

- Enhanced Safety: Quickly interrupt or restore power to prevent electrical hazards, equipment damage, or fires.

- User Convenience: Simple, intuitive operation for end-users, with options for remote control, tactile feedback, and visual indicators.

- Customizable Control: Wide variety of actuator types, switching mechanisms, and form factors allows for precise control in any environment.

- Reliability and Longevity: Quality materials and robust construction deliver consistent performance and long service life, even in demanding conditions.

- Energy Efficiency: Smart switches and automation systems reduce unnecessary energy consumption by scheduling, occupancy sensing, and load management.

- System Integration: Modern switches can integrate with IoT platforms, building management systems, and industrial control networks for centralized monitoring and control.

- Cost-Effectiveness: Properly specified switches can prevent costly downtime, maintenance, and equipment replacement by ensuring reliable operation.

Decision Factors: How to Select the Best Electric Switch

Selecting the right electric switch for your application involves evaluating several key decision factors to ensure optimal performance, safety, and value:

- Voltage and Current Ratings: Ensure the switch can safely handle the maximum voltage and current in your circuit. Overrated or underrated switches can lead to failures or safety hazards.

- Environmental Conditions: Consider exposure to moisture, dust, chemicals, temperature extremes, shock, or vibration. Choose switches with appropriate IP ratings or ruggedized designs for industrial or outdoor use.

- Actuator Type and Ergonomics: Select actuators that match user preferences and frequency of use—toggle, rocker, push-button, rotary, touch, or proximity.

- Mounting and Space Constraints: Assess available installation space; choose from panel mount, PCB mount, DIN rail, or surface-mount configurations.

- Control Requirements: Determine if you need manual, remote, or automated control, and whether the switch must interface with smart systems or PLCs.

- Durability and Lifecycle: Evaluate rated operating cycles, materials, and certifications relevant to your industry (UL, CSA, CE, RoHS).

- Cost and Availability: Balance performance requirements with budget constraints and lead times. Consider long-term maintenance and replacement costs.

- Compliance and Certification: Ensure the switch meets all relevant regulatory standards for safety, performance, and environmental impact.

Choosing the Right Electric Switch Manufacturer

To secure top-notch products, it’s crucial to partner with a manufacturer who truly grasps your unique requirements and provides high-quality electric switch solutions at a fair price. Explore the electric switch manufacturers listed on this page to find potential partners with proven expertise in your industry.

As you review manufacturers, keep your application specifications and requirements in mind, such as voltage/current ratings, environmental exposures, actuator preferences, delivery schedules, budget constraints, and certification standards. Request technical datasheets, product samples, or references from similar projects to assess quality and fit.

Select three or four manufacturers to engage with further. Initiate conversations with each, delve into your specific application, and evaluate their expertise, responsiveness, and after-sales support. A reliable supplier should offer customization, technical guidance, warranty protection, and flexible logistics to help you achieve your project goals.

Ready to start your electric switch project? Request a quote or design consultation from leading switch manufacturers, and take the next step toward superior electrical control and safety.

What is the difference between electric switches and circuit breakers?

While both electric switches and circuit breakers disrupt an electrical circuit, electric switches are primarily intended for manual or automatic control of electricity flow, whereas circuit breakers are designed to protect circuits by managing currents and preventing overloads or electrical faults.

How have electric switches evolved over time?

Electric switches have evolved from simple light switches invented by Thomas Edison to advanced devices with remote activation, sensor integration, and IoT capabilities. Key innovations such as the quick break switch, toggle switch, and modern smart switch features have improved safety, convenience, and application flexibility.

What are the main components of an electric switch?

The main components of an electric switch include conducting materials (such as copper or silver contacts), actuators (like toggles or buttons), terminals for wiring, a protective housing or enclosure, and contact mechanisms that define switching action (such as single-pole or double-pole).

What types of electric switches are available?

There are many types of electric switches, including toggle switches, push button switches, slide switches, waterproof switches, rotary switches, rocker switches, DIP switches, keylock switches, limit switches, relays, proximity switches, joystick switches, and transfer switches, among others. They vary by actuation method, control type, and application.

Where are electric switches commonly used?

Electric switches are used in residential lighting and appliances, consumer electronics, industrial automation, automotive systems, telecommunications, medical devices, security and safety systems, power distribution, aerospace, and renewable energy installations.

How does an electric switch work?

An electric switch works by opening (breaking) or closing (completing) an electrical circuit. When closed, current flows, powering connected devices; when open, the circuit is interrupted, turning devices off. Actuators like buttons or toggles change the switch’s state.

What should I consider when selecting an electric switch?

Key factors include voltage and current ratings, environmental conditions, actuator type, mounting requirements, desired control method (manual, remote, automated), durability, compliance with certifications, and budget. Consulting manufacturers for technical guidance can help ensure the right choice.

Electric Coils

Electric Coils Electric Switches

Electric Switches Electric Transformers

Electric Transformers Electronic Connectors

Electronic Connectors Electronic Enclosures

Electronic Enclosures EMI Shielding

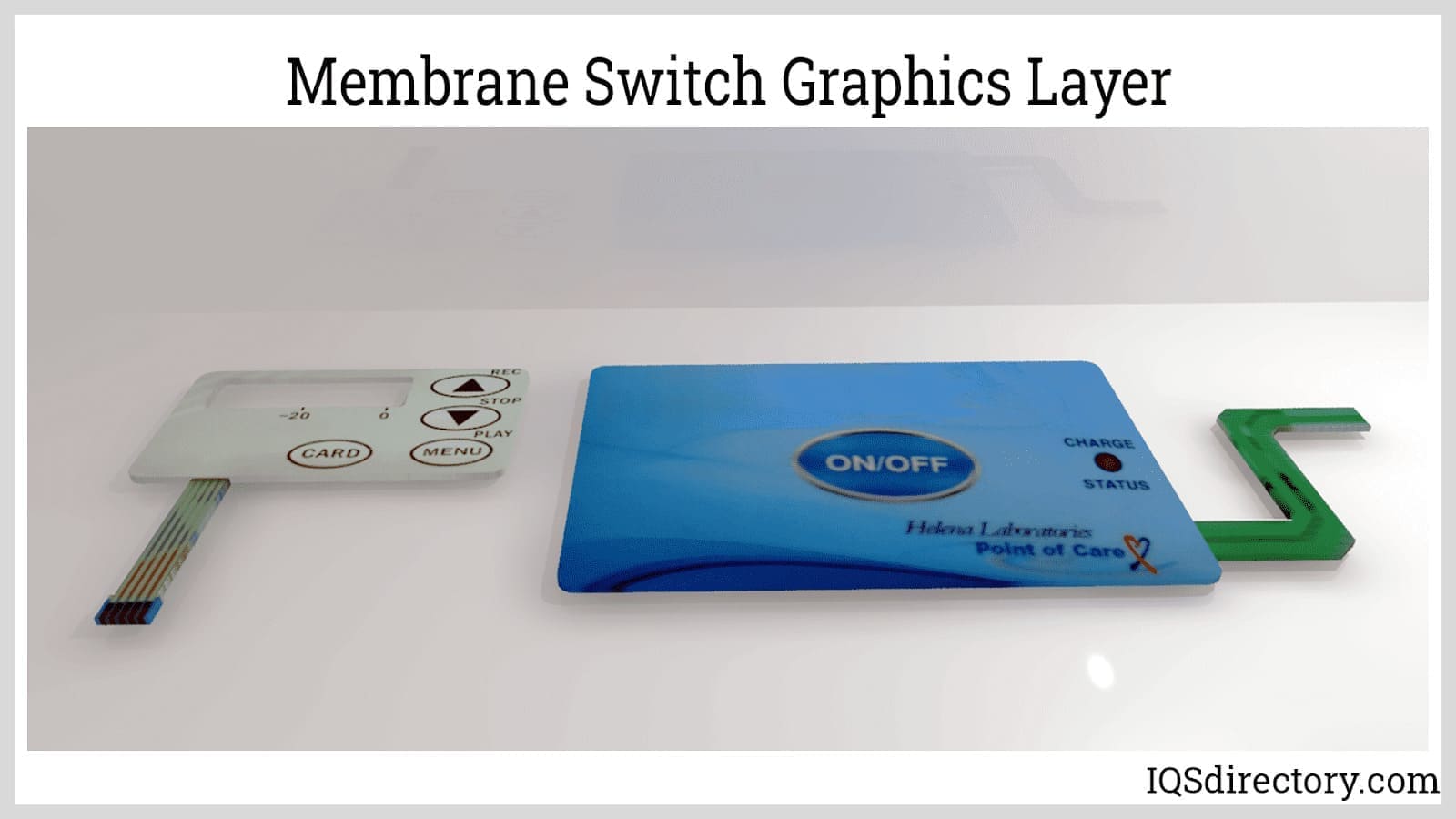

EMI Shielding Membrane Switches

Membrane Switches Power Cords

Power Cords Static Eliminators

Static Eliminators Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services